Since I started learning electronics I’ve successfully hacked together a couple of pieces of equipment like a temperature-controlled hotplate and a thermal flow meter. The trouble is that they currently consist of a rats nest of wires spread across my desk which get tangled easily and take ages to reassemble when I need to use the parts for something else.

I need to create some simple 3D-printable boxes to package everything together.

Fusion360

Generally courses are a bad choice because you can just use LLMs to directly work on the problem you are interested in. But for a sufficiently complex UI I want to just have someone tell me what buttons to click for a bit.

There’s a really good playlist on YouTube called “Learn Fusion360 in 30 days” which I strongly recommend. You really only need to go through the first four videos to get the hang of the UI before you can Google/GPT your way through the specific projects you want to work on.

Here’s a cool bottle I made in lesson three.

After that I transitioned to tracing some simple designs. I added mesh files from a fluidics paper that didn’t make their CAD files public and traced over them as a reference. I’d strongly recommend this approach. The third video in the 30 days series covers exactly this technique!

Fusion360 makes difficult things like threads extremely easy because it comes with a menu that lets you add any standard thread type to a surface. For any component you want to include in your design, there’s probably a menu or a YouTube video for it.

Here’s a nut with a hollow centre for tubing:

Now I want to create some boxes for my hotplate and thermal flow meter designs.

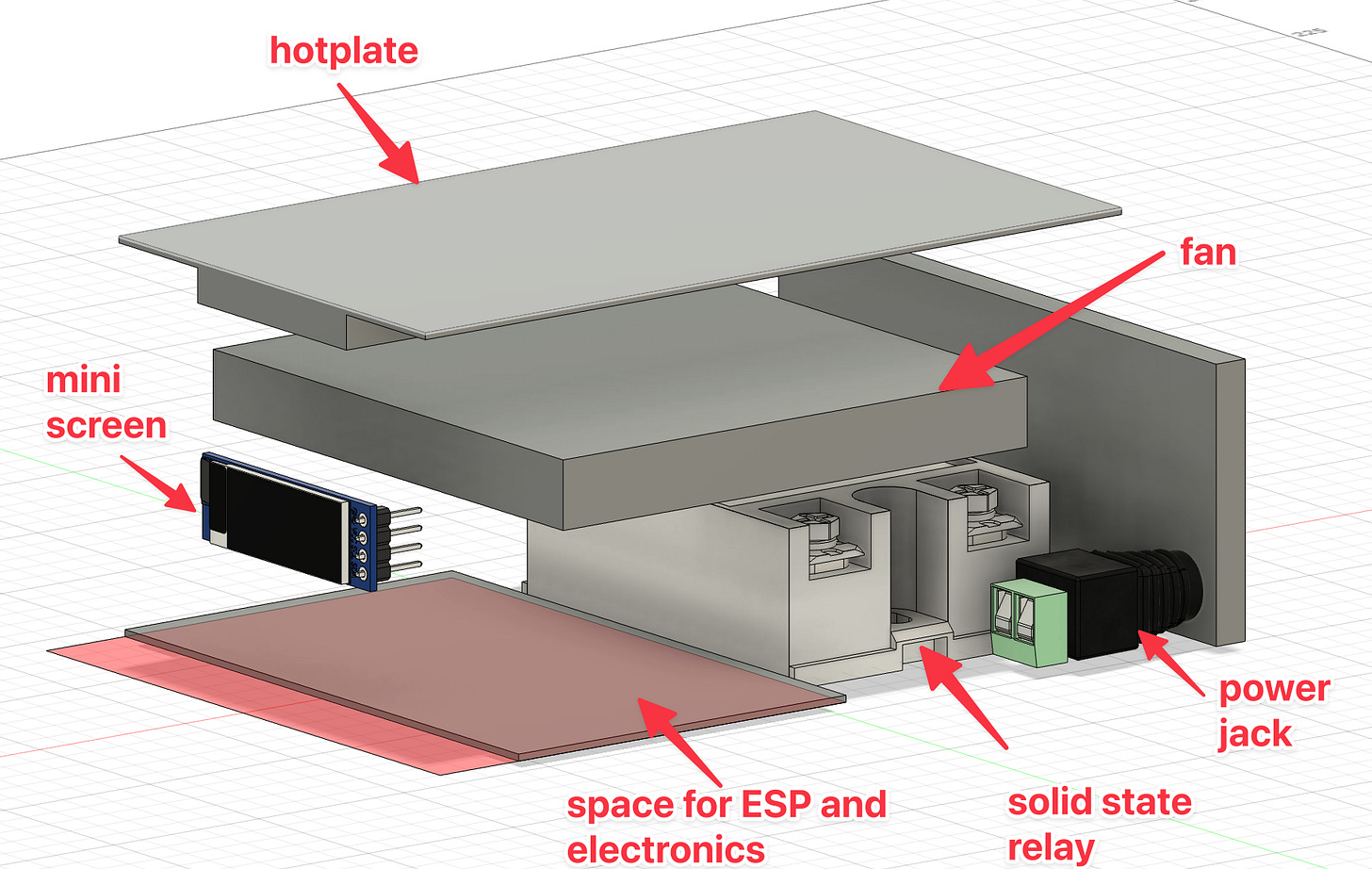

Hot Plate

To begin with I’ll just dump all of the parts on the screen in vaguely sensible places. For components like the mini screen and power jack I found CAD models online with accurate dimensions so I imported them into my design. I realised that some of the parts I ordered from AliExpress gave inaccurate dimensions so I double-checked everything manually with a ruler.

The main design constraint is that the hotplate heats to 260 degrees, while PLA (the plastic filament I will use to print the case) begins to soften at just 60 degrees! I’ll need to make the hotplate float above the base using screws otherwise it will melt.

Here’s the design - it’s super simple, just a box with a gap in the front for a screen, a hole for a power plug, and some holes in the lid so I can screw in the fan and hotplate above.

I found this video which walked me through building it. I just made a few modifications based on the needs of my project. I was in a hurry because the local library only lets you print once a week during a two-hour slot, so I rushed it to just get something printed without having to wait another week. I really need to get my own printer…

Thermal Flow Meter

Next I’ll design a box for a thermal flow meter. A thermal flow meter measures the flow rate of fluid in a tube non-invasively using a heater and temperature sensors.

I want to design the box based on this paper which shows some images of the box they created for their thermal flow meter.

They helpfully included some dimensions too.

I’ll modify the design to fit my project.

I’d like to have more freedom regarding sensor spacing.

I don’t need magnets, a photo detector or LED.

I’ll simplify the hinge.

I need to figure out wiring.

Based on these requirements I came up with an idea to split the flow meter into detached modules. This will give me the freedom to experiment with sensor spacing.

This is the bottom part:

And this is the top part.

I’ll also print a simple linear track I can slide each sensor module along and hold in place with tape for testing and calibration.

And that’s it! Now I will try to sweet talk the people at the library into printing for me outside of their weekly two hour window…

Next Steps

I hope this shows you that you can get productive with 3D design much faster than you think! It’s worth learning because 3D printing makes the iteration cycle for building projects much faster. It would be even better if I had one in my flat… Once the designs are printed I’ll share how they look and improve the next design based on testing.

As a possible alternative to the library, I assume you're familiar with makerspaces and similar, some of which are very reasonably priced?